Fuel handling system

Fuel was reloaded by a refueling machine while the reactor was in operation, without reducing its power. The main element of the refueling machine was the fuel casket with a biological shield performing the following functions:

Fuel was reloaded by a refueling machine while the reactor was in operation, without reducing its power. The main element of the refueling machine was the fuel casket with a biological shield performing the following functions:

- Ensuring hermetic connection between the machine and the top of the fuel channel

- Unsealing and resealing the fuel channel

- Removing a spent fuel assembly

- Measuring the inside dimensions of the fuel channel

- Loading a fresh fuel assembly

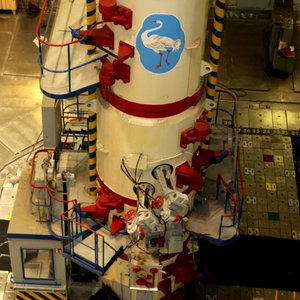

The machine had two systems of positioning over the fuel channel, optical/TV, and contact. The casket was attached to a carriage moving over a bridge that moved on tracks along the reactor hall. The machine was operated from the operator’s booth located behind the wall of the hall. The handling procedure was as follows: the machine was positioned exactly over the fuel channel and connected to it. The joint between the standpipe of the machine and the upper part of the fuel channel was then sealed. A special grabber of the machine clamped onto the fuel assembly bracket, and the fuel channel was unsealed. The grabber lifted the bracket with the fuel assembly and pulled it into the casket. A fresh fuel assembly was then placed into the channel and the channel was resealed after which the machine was disengaged from the channel and moved to the spent fuel reception area where the SN assembly was unloaded.